For The Transit Fans: Technology Profile: Air Brakes

If you've ever heard the distinctive "Pffft" noise that heavy trucks and buses make and been curious as to why they do this. Continue reading. If you have no interest in trucks or heavy vehicles this will be useless knowledge you can use to say you learned something today. If you ever want to get your CDL license so you can drive trucks and buses this information will help you pass your written and driving test.

On an 18-Wheeler Semi truck, The Red Knob activates the spring brakes on the trailer, The Yellow Knob activates the spring brakes for the rest of the system.

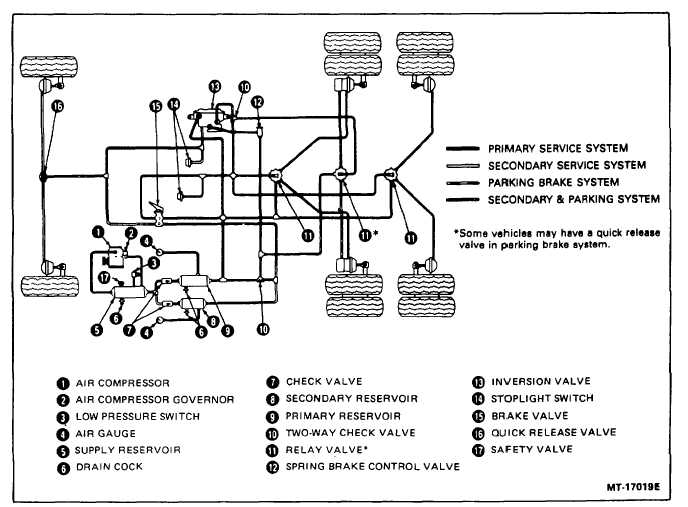

Airbrakes are used to stop heavy vehicles as they are more effective because the use of air pressure allows more force to be applied to the brakes than hydraulic force would allow. Air brakes uses a series of complex valves, tanks and hoses to move air through out the system. There are many components but once each component is understood and its function is explained the rest becomes easier to understand.

Truck Air Brake System Components Diagram

The Air Compressor is simply a pump. The Compressor pumps air into the system and it is mounted to the engine. It is usually belt or gear driven and begins to pump air as soon as the engine is started.

The Compressor Governor is a device which "governs" when the compressor starts pumping air and stops pumping air. The Governor tells the compressor to "Cut in" or start pumping air at around 100-90psi and to "Cut out" or stop pumping air at around 120-125psi.

Once air passes through the governor it is forced into a device called the Air Dryer (not shown). The Air Dryer (sometimes called a wet tank) foricbly removes moisture and other containminants from the air pumped from the compressor. This is the source of the loud (PFFFT) sound given off by trucks and buses. The sound is the water and dirt being forced out of the system. The air is then forced into the primary air tank (called the dry tank) where it is stored ready to be used to provide braking force.

The Primary Air Tank provides braking power to rear wheels. Most braking on trucks and buses is done with the rear wheels (where the vehicle carries the most weight) which is why it is the primary system.

The Secondary Air Tank provides braking power to the front wheels. Not as much braking force is needed at the front so the secondary tank is usually smaller.

Some vehicles are equipped with a third auxilliary air tank which is used to power other air powered devices on board such as Air Doors and Air Horns.

Now we have covered half of the system.

The Brake Pedal on a vehicle equipped with air brakes is actually a valve. Commonly called a Treadle Valve. Everytime you press on the brake pedal Air is let out of the tanks and into the brake chambers slowing the vehicle down. A (PFFFT) sound is heard doing this as well.

When air is released from the tanks it then goes into the Brake Chambers. There is a brake chamber at each wheel. Air Brake Chambers are designed as a fail safe system. When you release the Parking Brakes... Air forces very powerful springs back allowing the vehicle to move. If there isn't enough pressure to hold back the springs, the springs will activate and stop the vehicle right away.

Under normal braking Air forced into the chambers pushes on a device called the Pushrod. The Push rod turns air pressure into lateral motion. The Pushrod turns another device called the Slack Adjuster. When the Pushrod turns the slack adjuster they should form a 90' angle. If this does not happen that brake chamber is out of alignment and could cause an accident.

When the Slack Adjuster is turned a device connected to it called the "S-Cam" pivots on two points called the cam rollers. This action separates the Brake Shoes which then push and rub up against the brake drum. The friction caused by this is the same as it is in cars and it slows the vehicle down.

You now know how truck and bus air braking systems work, but it would be helpful to see it wouldnt it? welp ive got just the thing:

And If your still confused this one is easier to understand

Some Quick Numbers:

125 psi = Is a fully charged Air Brake System

130 psi + = is an overcharged system. This is an indicator that the Governor has failed and the pressue could build up and explode because the system is closed.

90 and 100 psi = is normal pressure range when driving normally. It will drop everytime you push the brake petal but the compressor will restore the air in a few seconds.

60 psi = Is when the low air warning light and buzzer will sound. If this happens while driving it is an indicator that the compressor and or governor has failed or it could be a leak in one of the air lines. At 60 psi you still have enough time to safely pull over and call for help.

40-20 psi = there isnt enough air in the system to hold back the parking/emergency brake springs and they will automatically activate.

-

2

2

2 Comments

Recommended Comments

Create an account or sign in to comment

You need to be a member in order to leave a comment

Create an account

Sign up for a new account in our community. It's easy!

Join the herd!Sign in

Already have an account? Sign in here.

Sign In Now